Printing your own stickers at home can seem simple, but small errors quickly add up to wasted materials, smeared ink, and poor-quality designs.

Whether you’re crafting as a hobby or creating stickers to sell, avoiding these common mistakes will help you get professional, durable results.

Table of Contents

1. Using the Wrong Sticker Paper for Your Printer

Many beginners assume that any sticker paper works in any printer. This isn’t true.

Inkjet-compatible materials won’t work properly in laser printers, and vice versa.

Using the wrong paper type often leads to poor adhesion, faded prints, or ruined sheets.

For a full explanation of printer compatibility and material choice, see the comparison in Inkjet vs Laser Printable Vinyl.

2. Forgetting to Adjust Printer Settings

Leaving your printer on its default settings can result in muted colors and blurry designs. To avoid this:

Choose the correct paper type (e.g., photo paper, glossy, or vinyl).

Print using ‘Best’ or ‘High Quality’ mode.

Adjust color density or saturation as needed.

For detailed steps to optimize your printing process, review How To Print Stickers With An Inkjet Printer.

3. Handling Stickers Before Ink Fully Dries

One of the simplest but most damaging mistakes is touching stickers before the ink sets.

Depending on material and printer type, ink drying times vary, but glossy and vinyl sheets generally take longer to dry.

Rushing this step causes smudging, ink transfer, and ruined designs.

If this happens to you, explore solutions in How to Stop Ink From Smearing on Your Printable Vinyl Sticker Paper.

4. Using Non-Waterproof Materials on Outdoor Projects

Regular sticker paper isn’t waterproof. Stickers applied to water bottles, cars, or laptops will peel, fade, or smear without using the right materials. Instead:

Use printable vinyl, which is inherently more water-resistant.

Apply laminating sheets to standard papers for added protection.

If you’re unsure how to properly waterproof your designs, read Top 5 Ways To Make Inkjet Prints Waterproof.

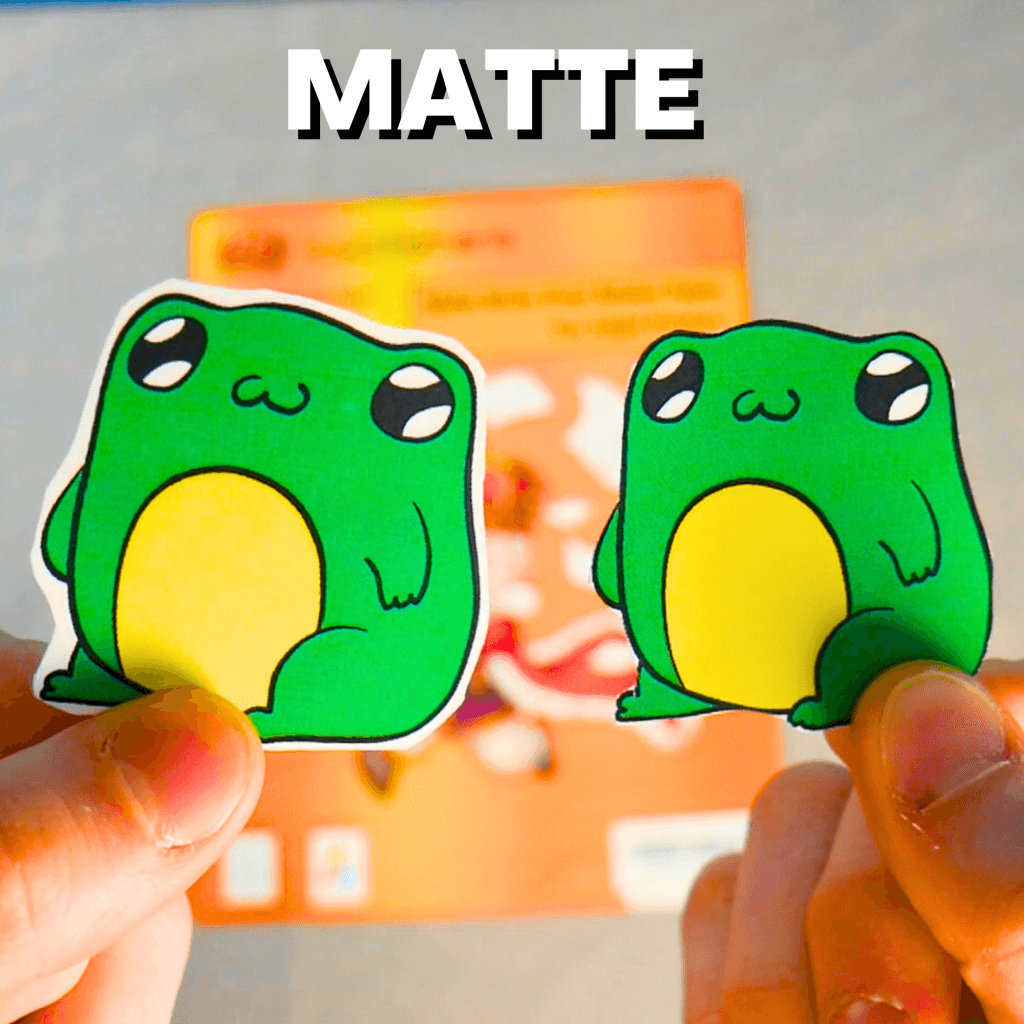

5. Overlooking Finish Type: Matte, Glossy, or Clear

The finish you choose affects both the look and usability of your stickers:

Matte works well for subtle, writable designs.

Glossy enhances color vibrancy and adds shine.

Clear printable vinyl allows backgrounds to show through for professional layering.

If you’re confused about the difference, see Clear vs White Printable Vinyl Stickers.

6. Oversaturating Designs or Using Poor File Formats

Highly saturated images often print poorly:

Ink pools and doesn’t dry evenly.

Designs can appear overly dark or bleed.

To avoid this:

Reduce saturation slightly before printing.

Use PNG or PDF for detailed designs, and avoid JPGs for images needing transparency or sharp lines.

For more on choosing the best file format, read JPG vs PNG vs PDF for Stickers – Which Prints Best?.

7. Skipping Test Cuts on Cutting Machines

Cutting machines like Cricut and Silhouette need adjustments for each new material. Skipping test cuts leads to:

Cutting too deep (slicing through the backing).

Cutting too shallow (designs won’t peel).

This mistake is especially common with printable vinyl, which is thicker than typical sticker paper. To learn how to avoid it, review How To Make Printable Vinyl Stickers With Cricut.

8. Forgetting to Protect Stickers Intended for Heavy Use

Waterproof materials resist moisture but still benefit from added protection against scratches and UV exposure.

Beginners often skip this step when creating stickers for outdoor use or products like water bottles. Two main protection methods are:

Laminating sheets (applied before cutting).

Clear spray sealants (applied after printing).

Not sure which method suits your project? See Laminating Sheets vs Spray Sealants: Which Is Best for Stickers?

9. Storing Sticker Paper Incorrectly

Sticker paper and printable vinyl are sensitive to:

Humidity (which curls sheets).

Dust (which interferes with printing).

Heat (which degrades adhesive).

Proper storage:

Keep sheets flat in sealed packaging.

Store in a cool, dry location away from direct sunlight.

You can find more handling and care tips throughout the Royal Elements blog.

10. Choosing Low-Quality Sticker Materials

Low-cost sticker papers often lead to:

Faded or streaky prints.

Weak adhesive that peels over time.

Inconsistent quality between batches.

To avoid frustration, compare options using the Top 25 Best Printable Vinyl Brands Compared, which evaluates print quality, durability, and compatibility across popular brands.

Conclusion

Avoiding these mistakes can save time, money, and frustration.

From choosing printer-compatible materials to adjusting your settings and adding proper protection, small details make a big difference in sticker quality.

For more guidance on materials and methods, explore the Royal Elements blog, where you’ll find tutorials, comparisons, and step-by-step guides tailored to beginners and experienced crafters alike.